Our work in polishing and staining concrete floors puts us in the role of working with someone else’s crafted surface—a poured concrete floor. The concrete company has come and gone. Now, during the finishing parts of a project, it’s our turn to go to work. Part of that work routinely puts us in a position to handle some of the joints in the concrete surface. This work includes filling and sealing control and expansion joints in the concrete surface.

Much like there are framers and finish carpenters in wood construction, we are the finish carpenters of concrete. We help create the best space by using concrete as a finished surface for a modern flooring solution. Instead of covering the concrete with a flooring material that wears out and ends up in a landfill, we work with the existing structure to create a sustainable and long-term solution. One that should last the life of a structure.

To most people, all these joints in the surface look the same. This isn’t the case. Control joints and expansion joints have different performance requirements and need to be treated differently. They need to be approached differently for the long-term sustainability of an installation and provide the best value for the client.

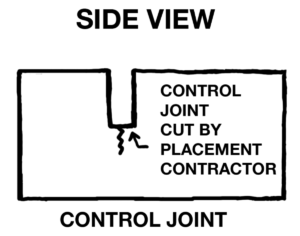

Control Joints

What are they? Control joints are joints placed by the concrete pouring crew as part of their installation process. This means that at the end of the day when they pour, or first thing the next morning, they run a saw along the concrete to create a cut line. The purpose of this joint line is simply to impart a weakened plane in the concrete, so the concrete cracks, at that predetermined point. This process hides the inevitable cracks of concrete in a linear grid pattern. You are controlling the cracking. Note that concrete still cracks, it’s just at the bottom of that joint.

Why fill them? Filled in control joints in polished and stained concrete floors provided an easier to clean surface. In wheeled traffic environments, the filler will act to protect the joint from future chipping or damage, and provide a smoother transition.

What do you fill them with? The most common filler for these is a two-part colored polyurea product. This is a semi-hard filler, which is more hard than flexible. Metzger- McGuire Edge Pro 80 is a popular choice.

New construction concerns. In new construction, there are a lot of moving pieces. As concrete cures and the initial moisture is pulled from the surface, there will be shrinkage that occurs. The WIN is to wait as long as possible to fill these joints. Ideally, it is towards the end of the construction process. If you don’t, the joints may look good on installation day but will break away from the concrete when the building is conditioned and dried out.

Expansion Joints

What are they? Expansion (or cold) joints are areas in a structure or slab that were poured at different times. Where two pieces of concrete come together or concrete and a different material come together and meet. Expansion joints are more susceptible to moving over time. The concrete may curl at the ends of each pour, or most noticeably around column pads, where more shifting over time may be apparent.

Why fill them? Filling in expansion joints in polished and stained concrete floors provides an easier to clean surface and a smooth and finished joint where debris or dirt could gather.

What do you fill them with? Because of the natural movement in these types of joints, a more flexible (rubber type product) is recommended. These products have more flexibility and can maintain the performance longer in movement type situations. Products like NP1 and Dymonic 100 are common materials. These cure to a flexible rubber-type feel. Please note that flexible expansion joint filler does not protect the edge of the slab from damage.

Examples of Expansion Joints.

- If a concrete company pours a 50’ x 50’ slab on day 1 and come back and pour another slab another 50’ x 50’ slab on day 2. That joint between the two different slabs is called an expansion joint.

- If the column pads are poured for a building and then the slab is poured a few weeks later, the difference between these two pieces of concrete is also called an expansion joint.

Next Steps

We have found the best way to approach projects is having clear communication during bidding and submittals for what products will be used and where. When things like this are called out in specifications, and the polished concrete process is done in the right part of the schedule, the client gets the best product that continues to perform for years and years.

Note: Nothing we do inherently changes the structure of the concrete surface. Joint Fill products cannot stop cracking, shifting, movement, or any other common concrete concerns.

Of course, reach out if we can serve or help with one of your projects. Our goal is to balance real-world practicality with good design through our installations, specifications, and recommendations. We are grateful for the role you allow us to play in your projects.

1 – The Summit Event Center 2 – The Landing Beer Co. 3 – Warsaw High School

4 – Lehman YMCA 5 – Auburn Cord Duesenberg Museum 6 – Connelly’s Do It Best Hardwear

Want to schedule a Lunch and Learn for your team, or interested in specifications for an upcoming project? Click here for more information or send me an email at create@dancerconcrete.com