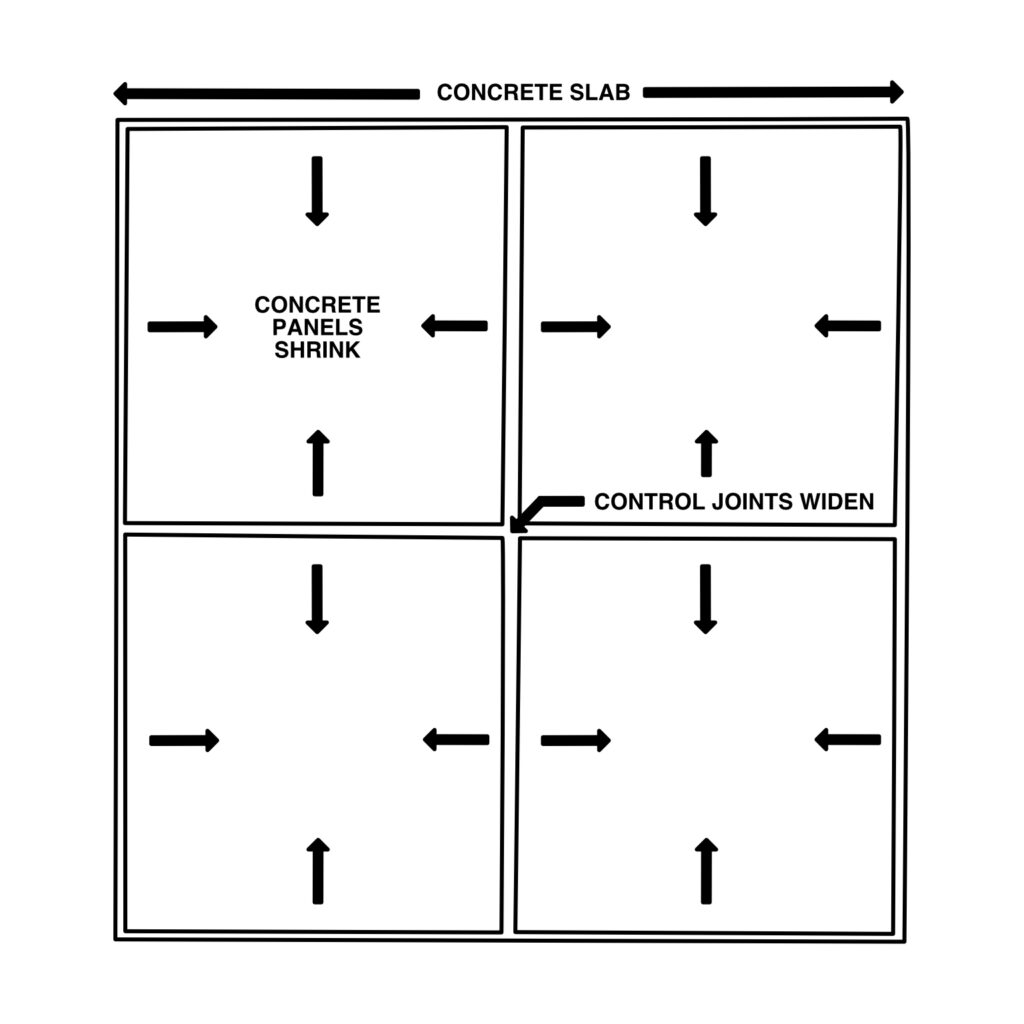

In our project planning, we often get the question, “When is the best time to joint fill?” For months after new concrete is poured, the slab will shrink as the water used at installation evaporates. This causes the linear control joints to widen as the cut concrete panels shrink. It is best to wait as long as the schedule allows to fill joints in order for you to get the BEST WORK on your floors.

WHAT IS JOINT FILL?

We use a semi-rigid product made for polished concrete operations to fill and protect joint edges. It is colored to match the existing concrete floor colors. Read more about our Joint Fill Process here.

WHEN DOES IT HAPPEN?

- The building is closed-in and temperature-controlled.

- The space is well-ventilated.

- The joints are dry.

- The floor has been curing for a minimum of 30 days. In best-case scenarios, the floor has cured for 60 to 90 days.

- Refrigerated environments such as walk-in coolers have been at operation temperature for a minimum of 7 days.

The WIN is to wait as long as possible to fill joints, usually toward the end of the construction process. If you don’t, the joints may look good at installation but will break away from the slab when the building is conditioned and dried out.

Our product supplier, Metzger McGuire, has put together a great technical resource on the timing of joint fill.

INTERESTED?

Need to time your next project just right? Reach out to us to get started on your quote. Our Project Leaders, Jacob, Nathan, and Ben, are here to help you get the BEST WORK for your floors.