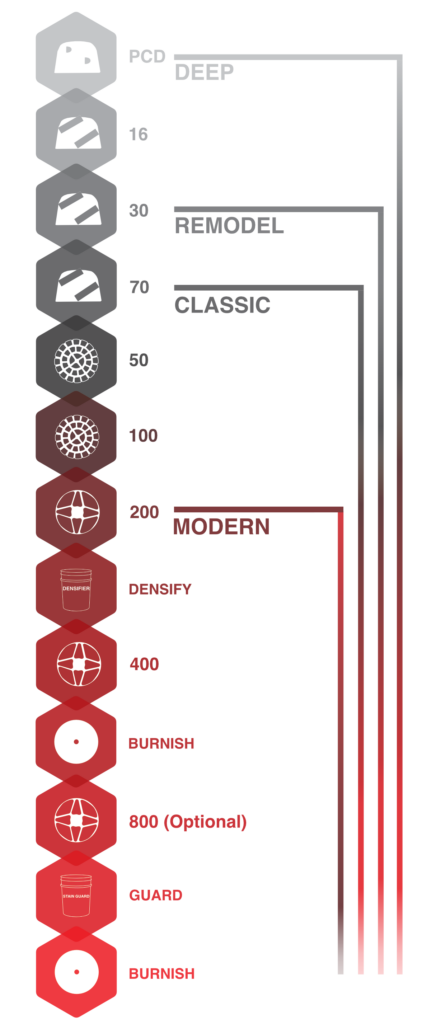

The polished concrete process includes grinding, honing, and polishing with bonded abrasives and treating the surface with a penetrating hardener. Think of grinding concrete as similar to sanding wood. You start with the more aggressive grits and get finer as you move up through the grits. We use large machines and hand grinders with tooling to grind down the levels of concrete. We wrote about when polishing concrete takes place here.

THE GRIND

For a Classic polished system, we will start with a 70-grit and work up to a 400-grit. There are about six passes with our grinding machine for our Classic Polish system. This standard gives us a satin finish, which is a popular base level for your floors.

For a Deep polished system, we use harder tooling called PCD – a polycrystalline diamond – and bush hammers. These toolings allow us to dig deep into the concrete before we move up the grit sizes to finish the polishing process.

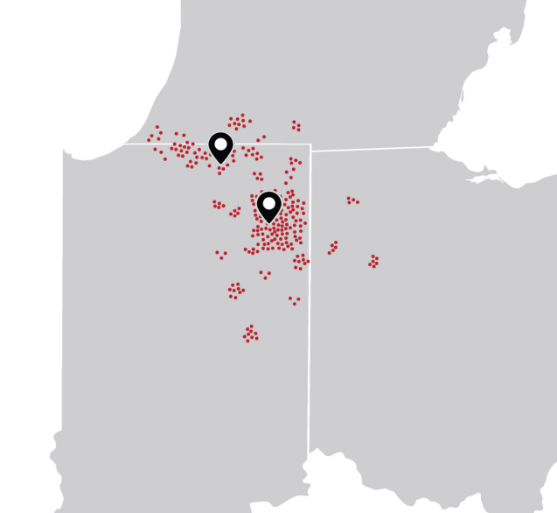

Our Modern, Classic, Remodel, and Deep systems give you unique aggregate exposures. Aggregate is the building block of concrete – the sand and stone that gives concrete its character. In the Fort Wayne, Indiana area, we find that the exposed stone is crushed Indiana limestone. In the South Bend, Indiana area, the aggregate we see is gravel. We like the Lightwater Quarries’ write-up of the difference between limestone and gravel seen in concrete.

AGGREGATE LEVELS

Class A

Cream Aggregate: A polished surface with little-to-no aggregate exposure and some light sand exposure. Very little of the concrete surface during the polishing process.

Class B

Fine/Sand Aggregate: Also known as a Salt and Pepper finish. The majority of exposure displays fine aggregate with some medium aggregate in random locations. Removes not more than ¹⁄₁₆” of the surface during the grinding and polishing process.

Class C

Large Aggregate: Heavy aggregate exposure with some light sand visible in random locations. Removes not more than ¹⁄₄” of the concrete during the process.

The Modern polished system is a Class A exposure, which hones the cap of the concrete with a cream finish. Our Classic polished system will give you a Class B aggregate exposure; this Salt and Pepper finish is what you think of as a classic polished concrete finish. The Deep polished system will be a Class C aggregate exposure, highlighting the large stones used in concrete. A Remodel system falls between a Class B and C exposure depending on the condition of the existing slab.

FINISHING TOUCHES

We use two products to pair with our concrete grinding: densifier and stain guard.

An integral part of the polished concrete process, densifier is applied to the floor after the main portion of grinding is completed. Concrete densifier chemically reacts with concrete to close up the pores of the surface. This makes your concrete floors harder, denser, and dust-proof.

Applying stain guard is the final step in the concrete polishing process. This product is a water repellent that adds stain protection and long-term durability to concrete floors. Stain guard is burnished after the application is dry to smooth and shine the floors.

Polished concrete is a sustainable flooring option, as it uses the existing structural elements of a building to create a finished surface. There are a variety of custom options available for polished concrete, including dyes, stains, decorative lines, and logos. Polished concrete offers one of the most economical lifetime costs of any floor.

INTERESTED?

Whether it’s polishing new or old concrete, we are here to help. Get in touch with a Project Leader to discuss your polished concrete project today. We are here to deliver BEST WORK for your concrete floors.