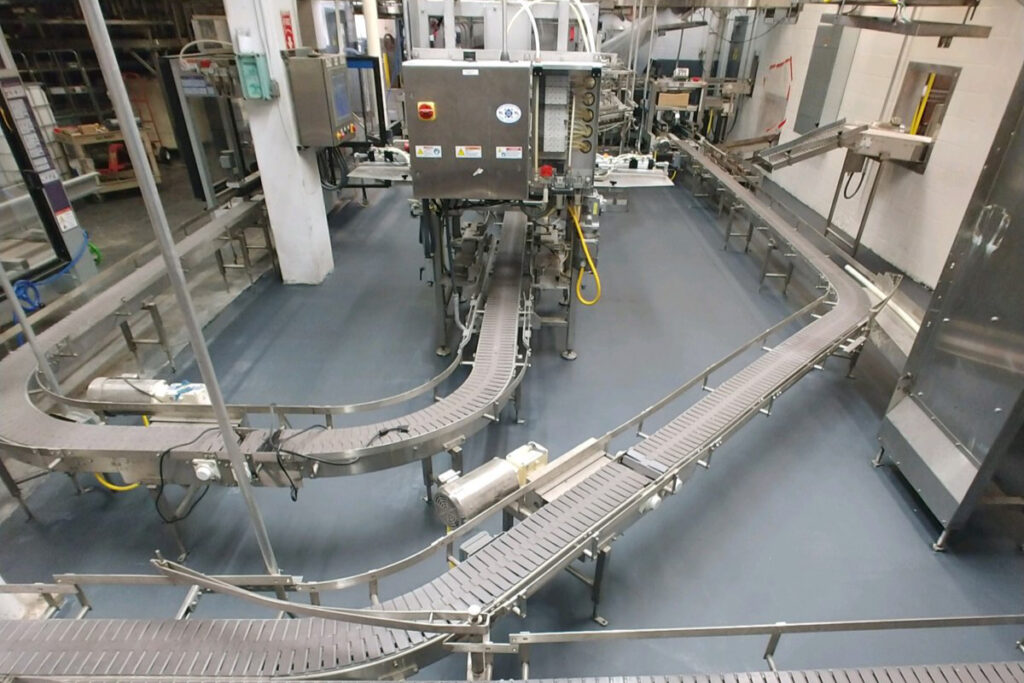

Our TreadWell Urethane Mortar floor systems are designed with abusive floor settings in mind. They offer all the benefits of a broadcast epoxy system while being impact-resistant and withstanding of extreme temperatures.

BENEFITS OF A URETHANE MORTAR FLOOR

From Dur-A-Flex’s website, the benefits of this flooring system include:

- Seamless: Monolithic integration allows wall-to-wall coverage and sloped drains to prevent standing water. Nonporous surfaces reduce areas for bacteria to hide.

- Durable: Floors endure the wear and tear from daily exposure to high foot traffic, potent cleaning compounds, and toxic food acids.

- Low maintenance: Floors perform better and last longer over time with minimal care compared to conventional tile or dairy brick options.

- Thermal shock resistant: Dur-A-Flex floors can withstand cycling between hot and cold temperatures without delaminating, peeling, or cracking.

- Resistant to chemicals: Various topcoat options stand up to heavy cleaning agents, like solvents, sanitizers, and alkaline cleaners.

- Cost savings: These durable floors can limit the costs associated with frequent repairs or replacement, in addition to eliminating the downtime that comes with them.

- Safe: Multiple textures are available to protect against hazards that can cause slippage during cleaning or facility operations.

WHAT KIND OF SPACE WORKS BEST?

Our TreadWell Urethane Mortar system is great for:

- Food Grade Facilities

- Industrial/Commercial Kitchens

- Heavy Duty Manufacturing

- Breweries

- Areas where thermal shock is a concern

This is a system customizable to your needs. There are solid color options, as well as decorative quartz and decorative chip options available.

LET’S GET STARTED ON YOUR PROJECT

Our Project Leaders, Jacob, Nathan, and Ben, are here to help you get the BEST WORK for your floors, so reach out today to get the ball rolling on your next epoxy project.