Polished concrete can expose the building blocks of concrete: aggregates. These stones are used with a cement binder and other additives in concrete pours to bring strength to the final product. Concrete aggregates generally range in size from ⅜” to 1½”, and their shapes depend on their processing.

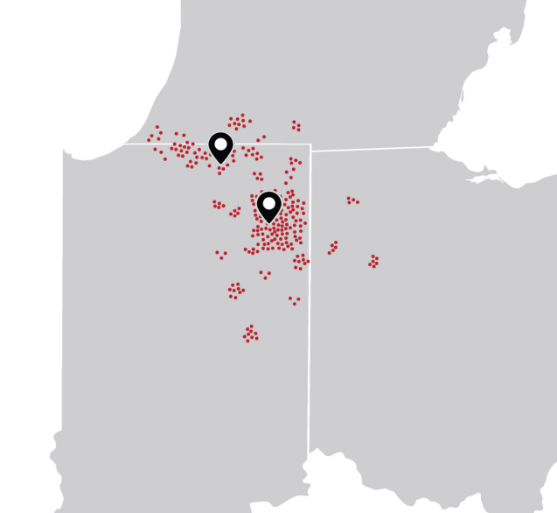

When you want an even, consistent deep stone exposure, we offer a Class C polished concrete system: StrongTread Polish – Deep. When we install this system, grinding and polishing removes about ¼” of the concrete surface to reveal the large aggregate throughout the floor. Here in northern Indiana and northwest Ohio, we see two types of concrete aggregates: gravel and limestone.

GRAVEL

Gravel, also known as river rock, is harvested from rivers, lakes, or seabeds. This aggregate varies in color and size and has smooth, rounded edges from naturally tumbling in the water over time.

LIMESTONE

Limestone is processed in quarries through blasting and crushing, leaving the aggregate jagged. While irregular in shape, it has been manufactured to specified sizes. It is almost always light gray in color once polished.

MAKE DESIGN-DRIVEN DECISIONS START TO FINISH

Our Team can offer recommendations and samples to help make those decisions before concrete is poured, so reach out and tell us about your project. Our Project Leaders are here to help you make the BEST choices in your design process.