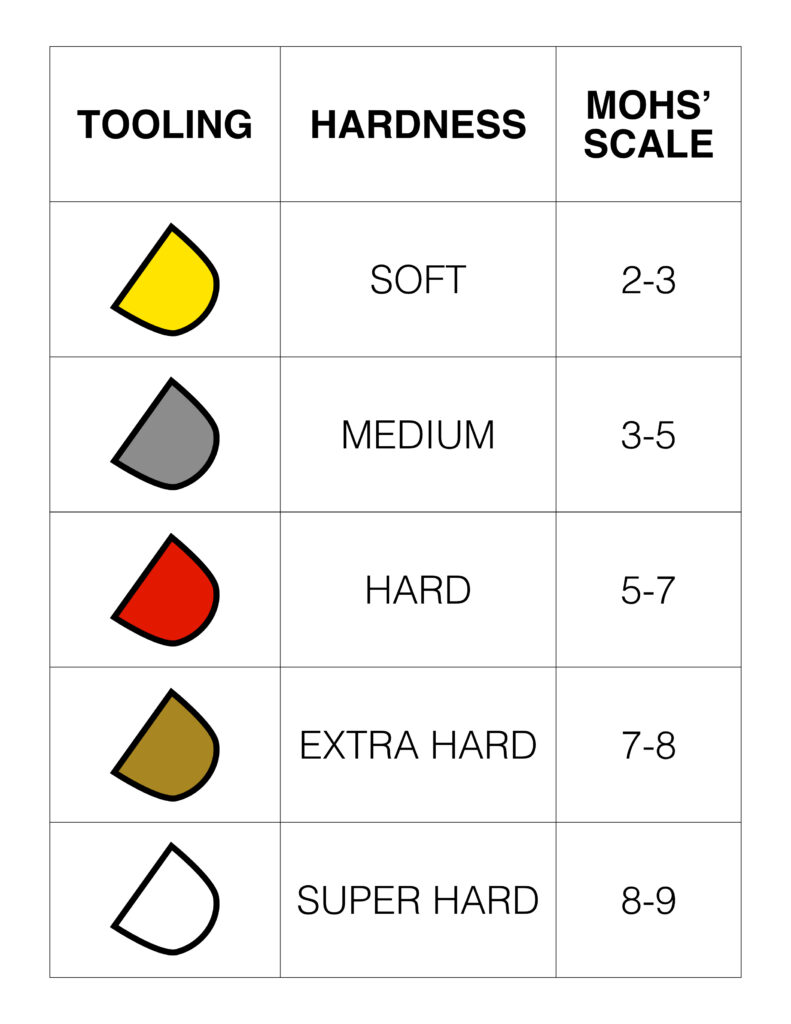

The metal tooling used to grind, polish, and hone polished concrete floors is determined by the concrete floor’s hardness. Concrete hardness affects how the abrasive tooling bonds to the concrete to create an even and smooth surface as we install our polished concrete systems.

MK Diamond has written a deep dive into the four factors that affect concrete hardness: Compressive Strength, Age of the Concrete, Aggregates and Sand, and Steel Reinforcements. To determine the concrete floor’s hardness, Dancer Concrete Design uses the Mohs’ Scale.

HOW WE USE THE MOHS’ SCALE

We use the Mohs’ Scale to determine the concrete surface’s hardness. This Scale informs what metal tooling we use to grind and polish your floor. By using the right tooling, we get a smooth, even surface with no visible scratches.

The metal tooling we use comes in several different hardnesses, which we choose depending on the results from the Mohs’ Hardness Test Kit of the concrete slab. Each DCD Team has a Test Kit with four double-ended pin vises that they use to scratch the concrete surface. If the scratch test leaves a mark, we know that the bond of that hardness is good; if the scratch test instead glides across the surface, the bond is too soft to be effective.

Polished concrete floors are both mechanically finished and treated with a penetrating hardener. Firstly, the mechanical finishing includes grinding, honing, and polishing the floor with bonded abrasives – also known as metal tooling. Then, the floor is treated with a penetrating hardener. The concrete hardener, also called a densifier, gets deep into the concrete to help harden and dust-proof the surface.

WATCH IT IN PRACTICE

GET BEST WORK FOR YOUR FLOORS

Your floors are an important part of your project, so don’t settle for anything less than BEST WORK. Start a conversation with one of our Project Leaders, they are here to help you each step of the way. Reach out today to get the ball rolling on your next project.