We get it – clients want in, and we all have schedules to keep around a job site. There are also real risks associated with finishing concrete floors before industry-standard conditions are met that fall outside our warranty.

Industry-standard conditions for polished concrete and epoxy coatings include allowing concrete to cure for a minimum of 30 days with 7 days of temperature control.

THE 4 MAJOR RISKS

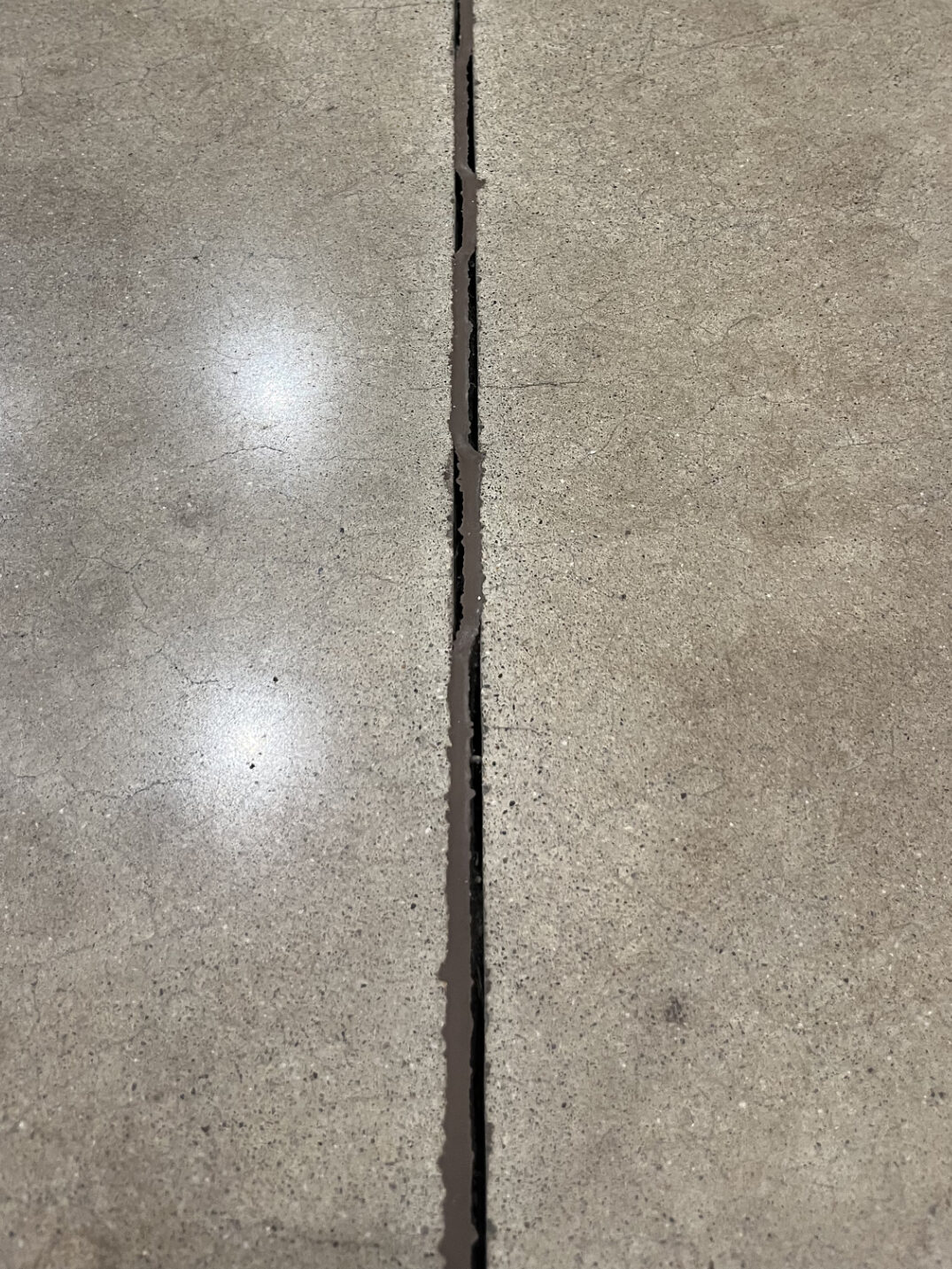

1. Joint Separation. As concrete cures, there will be slab shrinkage. If joints are filled too soon, it is normal for some joint separation to occur. Our warranty will not cover this repair, as this is a known risk when filling joints. Cutting out the joint and re-filling at a later date is an option.

In epoxy floors, you may see a shadowing effect from the control joint grid. Again, this is a normal part of epoxy floor coatings.

2. Efflorescence. When concrete is poured, it contains excess water that will end up coming out over time. Most of this will happen when HVAC systems are kicked on and the building is enclosed. During this process, the water will carry salts and minerals from the concrete as it travels out the top of the slab.

As the moisture/water evaporates, it will leave the mineral salts on the surface of the concrete, which resembles grainy dirt with a whitish appearance. Efflorescence has more to do with the concrete mix ingredients, placement, how much water was used during pouring, and the temperatures and humidity leading up to the finish work than it does with the concrete sealing/polishing process.

It’s a royal pain, but efflorescence will go away with time. Running a dehumidifier will help speed up the process as long as the slab has a vapor barrier. If this is short-lived, all will be well – simply cleaning the surface will remove the efflorescence. In some prolonged instances, the floor may have lost its sheen and needs to be refreshed to return to its original luster.

3. Epoxy Delamination. We will test floors for moisture before coating. Selecting the right primers or systems based on these readings helps keep the floor from delaminating from the concrete. Again, the proper curing and temperatures reduce this risk.

4. Damage. Our floors are extremely durable for their specific use, but continuing construction might be the most abuse these floors will ever take. Scheduling our work after overhead work is done and right before casework is installed is the best place in the construction schedule for most of our floors.

Our goal is to balance real work practicality with good design principles. Feel free to reach out to our Project Leaders, who understand these risks and know you have a schedule to keep.