Polished concrete floors have become very popular in the last few years. One of the main reasons these floors have seen extraordinary growth is the long-term durability of the finished surface. Concrete is the most widely used building material for its strength and longevity. In the past concrete had been covered by another flooring material, coated with a thick sealer, or left untreated. When left un-treated concrete can stain easily, will dust, and will be difficult to clean.

A fully polished concrete floor consists of making progressive passes with diamond abrasives to refine the surface of the cement, use of a reactive concrete densifier, and a final stain guard product.

This full polishing process for an older concrete slab might consist of the following steps

- 40 grit – metal bond pass

- 80 grit – metal bond pass

- 150 grit – metal bond pass

- 100 grit – hybrid metal/resin pass

- 200 grit – resin bond pass

- 400 grit – resin bond pass

- Application of color (if applicable)

- Application of densifier

- 800 grit – resin bond pass

- Application of concrete guard product

As you can see the process for this fully polished concrete floor is very extensive. This is the recommended solution for a high shine floor for retail, churches, commercial establishments, and other high foot-traffic areas. Check out projects we have completed this full polishing system on by clicking here. The multiple polishing passes create a surface that is hard to dull and easy to clean. This entire flooring solution, although great for these high-traffic environments might be out of budget for certain projects.

We have found a high-performance alternative that results in a near polished finish that works great in industrial areas, warehouses, barn floors, commercial garages, repair facilities, and agricultural applications.

This process consists of a light grinding to open the concrete surface, a double application of a reactive colloidal silica concrete densifier, and a stain protector. This floor results in a durable low-cost alternative to a fully polished concrete surface. Unlike other concrete sealers that can peel, flake, or dust, this system conditions the existing concrete surface to create a harder and denser concrete surface for maximum durability. On new concrete, this process can cost between $1.25 – $2.00 sq. ft.

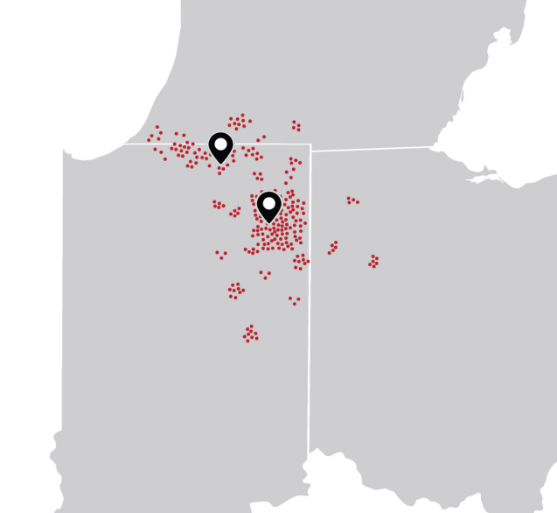

My company, Dancer Concrete Design, has recently completed some projects with this sealing system around Fort Wayne, Indiana. Check out this agricultural project we completed in North Manchester, Indiana.

Thanks for reading.

Nick Dancer, Owner Dancer Concrete Design

Fort Wayne, Indiana – 260.748.2252