Over the summer, we got a call from a GC. They were troubleshooting a school gym with a cracked concrete floor and wanted to know if it could be repaired. This floor is a mezzanine that has practice half basketball courts and bleachers that fold out for seating when there are games. This weight variability is the culprit of the cracking. The slab itself is a precast, pre-tensioned slab that was designed for this space. The topping slab couldn’t withstand the changes without cracking. They needed something flexible that could.

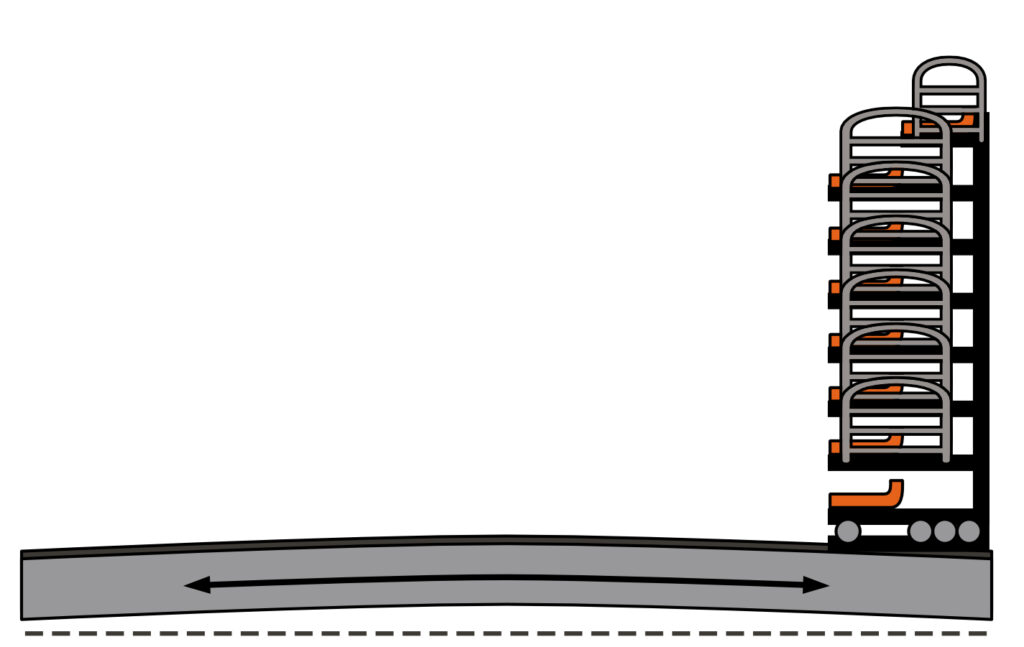

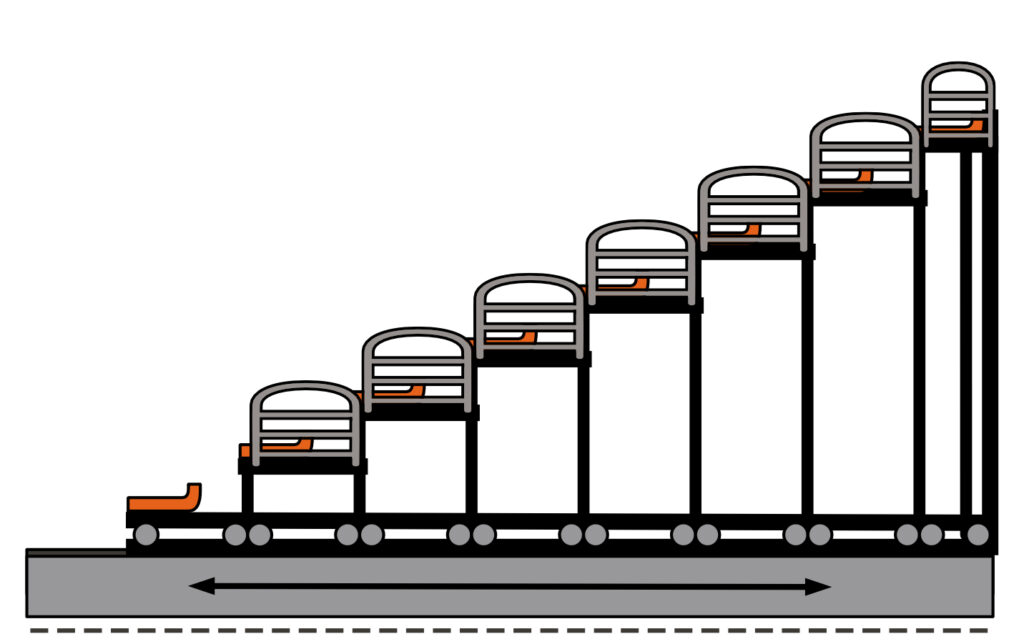

Pre-tensioned Concrete

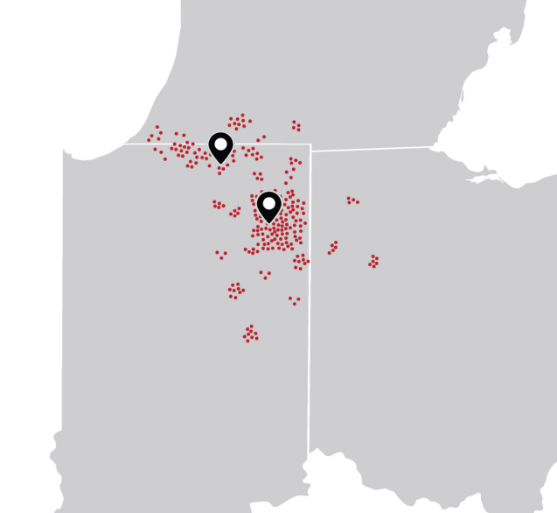

In the above graphic, the topping slab is a uniform thickness across the pre-tensioned concrete slab.

Precasting a concrete slab under tension makes sure the live load, or the weight that changes over time, is supported without the slab cracking under pressure. Instead, the slab flexes under the load. Practical Engineering has a good video that explains the nitty-gritty of what pre-tensioned concrete is, how it’s done, and why it works.

Pre-tensioned concrete is designed to flex instead of crack. The finished floor needs to be able to flex with the slab instead of break. This is the problem the school was having—the topping slab that finished the floor was cracking instead of flexing with the changing weight.

Flexible Floors?

A traditional overlay was going to have the same cracking issues the topping slab was having. Traditional epoxies are also rigid and not designed to bend. We talked with a supplier who suggested a rubberized epoxy. It was designed to be a waterproofing barrier. The traits that make it great at waterproofing also makes it flexible.

This flexibility is exactly what this high school’s gym deck needed to be crack-free.

TreadWell Flex+

This indoor system starts with preparing the floor for the epoxy application. Then, the rubberized primer is installed. A solid color body coat is applied on top. Decorative vinyl chips can be broadcast into the floor to help with traction, wear, and aesthetics. A polyurea topcoat is used to encapsulate the chips and leaves a finish that’s durable and easy to clean.

The unique nature of TreadWell Flex+ makes it a great option on a second (or higher)-story floor. It can adhere to a concrete or wood substrate. Its waterproof nature makes it a great option in places where water is a concern.

Being a TreadWell system, Flex+ can be customized to fit the needs of the space with all of our epoxy options—from additional traction to minimize slipping risks, to line stripping or court markings. TreadWell Flex+ has all of the benefits of a traditional epoxy system—it’s just flexible.

Basketball court lines, decorative chips, and a flexible epoxy floor make this multi-purpose gym deck functional, durable, and long-lasting.

Interested?

Have a floor that needs a flexible solution? Reach out to our Project Leaders, they are flooring problem solvers. Tell them what’s going on with your floor, and they’ll recommend a customized flooring solution for your space.