Polishing and Custom Staining

When Dancer Concrete Design explains a project to our clients, we give them multiple options on how we can complete the floor. For polished concrete that includes what finish level they want (shine level), reactive stain vs. dye, densifying, and various guards we can apply to protect the floor. While the options may seem overwhelming, we break them down and explain them in detail so clients know exactly what they are and their benefits.

For this residential project, we had two separate areas. One area was going to be polished and have a reactive stain applied, while the other area, a mechanical room, was to receive a “guard and burnish” treatment. Our polishing process included grinding the floor to remove the cure and seal, and going through the necessary passes to bring the floor to an 800-level shine – a reflective shine that is easy to maintain. We then cleaned the floor, added the custom stain work, (with a mixture of black and sand), rinsed the floor, densified, and finished with a final polish.

For the mechanical room, we added RetroGuard to the concrete to protect it from oils, liquids, and other contaminants that may stain the surface; then we burnished it for the finished look. While it may seem like there are many steps to the process, our job at Dancer Concrete Design is to provide a floor that will last, will look good and will stand up to the traffic and not experience the “everyday wear and tear” that a lot of flooring solutions see. Making sure we follow all of the steps is crucial to the success of our floors and the satisfaction of our clients.

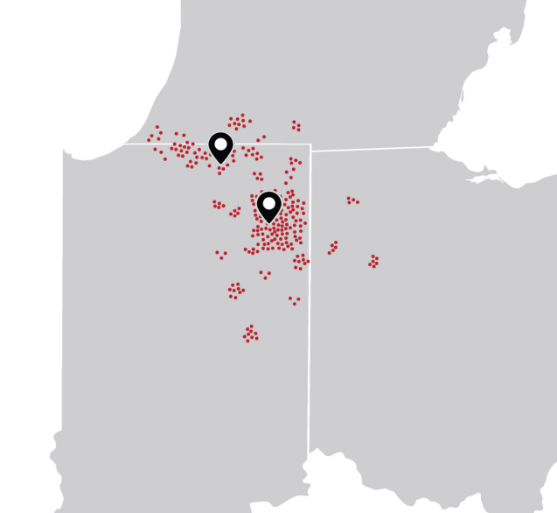

Location

Fort Wayne, Indiana

Services

Finishes

High Sheen

Black and Sand Mixture