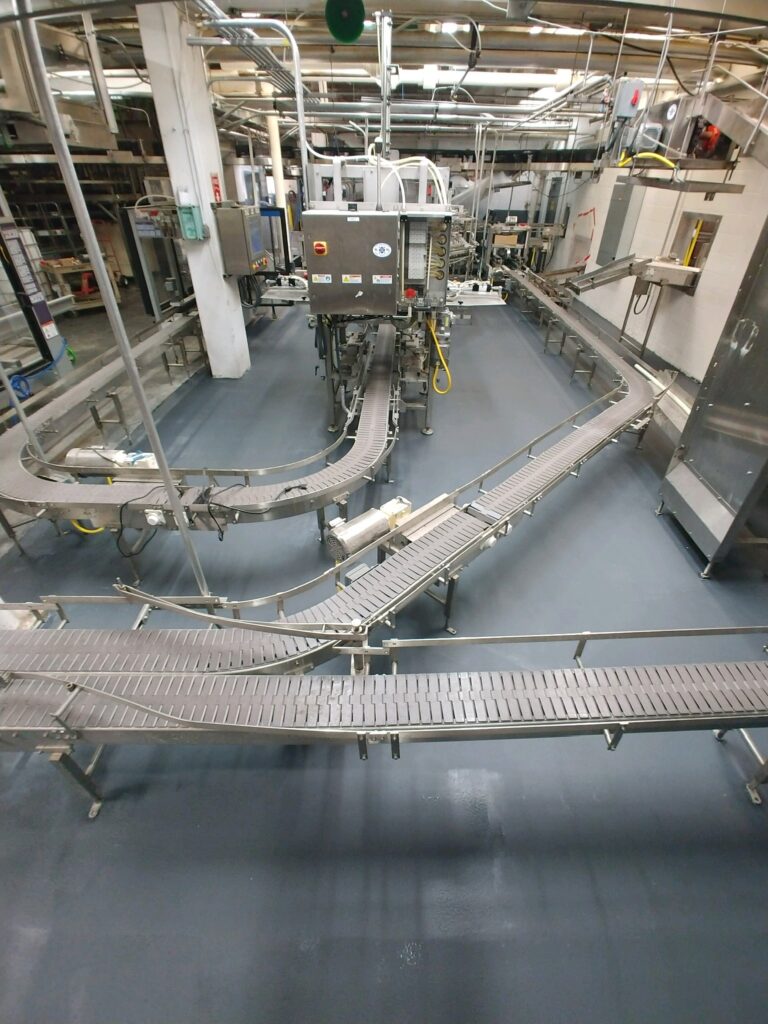

When choosing an epoxy flooring system for a food-grade processing facility, it’s important to find the best design that balances budget, looks, durability, and cleanability.

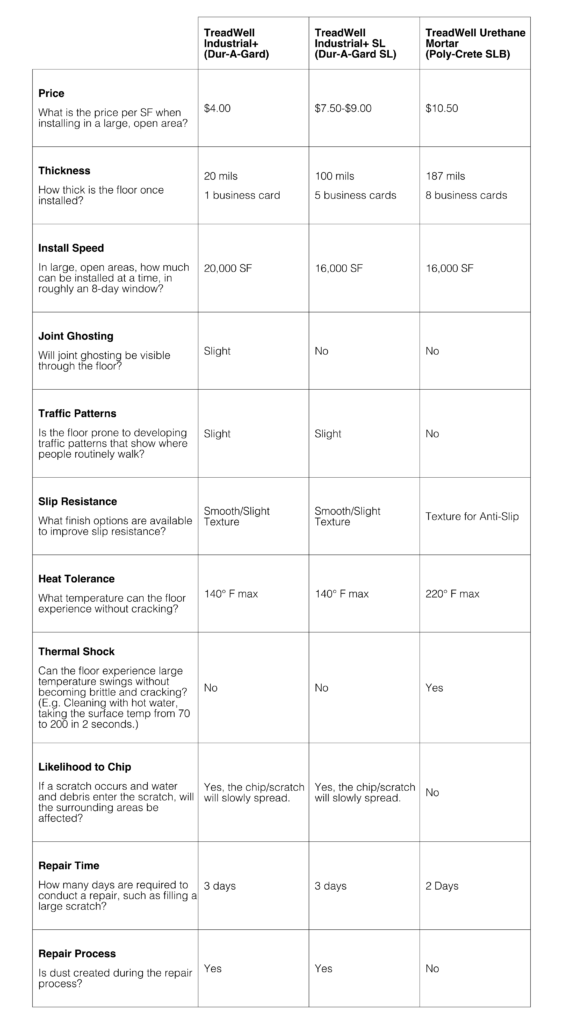

We have the following options to compare Good, Better, and Best systems.

Good: Treadwell Industrial+

Products Used: Dur-A-Gard Epoxies and Armor Top Urethane

Thin-Mil Epoxy Flooring System

Thickness: 20 mil

Budget: $4 / SF

Why we like it….

This is the base option when thinking about an affordable way to coat a concrete floor. This can get the job done, provides a newly coated and colored floor, and will meet requirements for a non-porous surface.

- Most Affordable. It gets the job done.

- Good abrasion resistance for foot and light wheeled traffic.

- Multiple Finish Options – Sand profile, smooth with griT, smooth with griP.

- Good chemical resistance.

Limitations…

Because of its affordability, this system is one of the thinnest mil profiles of epoxy installations. Although having great abrasion resistance against light wheeled traffic, its gouge resistance is weak. A nail on a skid or a sharp object will puncture the system and dig down to the concrete. This can create a weak spot in the floor that can cause delamination.

- Minimal impact resistance and gouge resistance

- Shadowing of joints and minor cracks in time

- Limited temperature and thermal shock protection

- Must be below 75% RH for normal installation. Moisture Mitigation with a 5-Year warranty is available.

Better: Treadwell Industrial+ SL

Products Used: Dur-A-Gard Self Leveling, Armor Top Urethane

Medium-Mil Epoxy Flooring System

Thickness: 60-100 mil

Budget: $7.50 – $9 / SF

Why we like it….

The Self Leveling (SL) version of the Industrial+ flooring offers some additional impact and abrasion resistance over the regular system. This system can be used on worn floors and the thickness better hides surface imperfections and joints, providing a visually flatter floor.

- Available in 60 mil or 100 mil thickness.

Limitations….

- Limited temperature and thermal shock protection

- Must be below 75% RH for normal installation. Moisture Mitigation with a 5-Year warranty is available.

Best: Treadwell Urethane Mortar

Products Used: Polycrete SLB, Shop Floor, Armor Top Urethane

(Additional topcoat options are available, such as Novolac for increase chemical resistance)

Heavy Use – Cementitious Urethane Mortar

Thickness: 187 mil (3/16″)

Budget: $10.50 / SF

Why we like it….

Urethane Mortars are the go-to choice for Food Processing Facilities for where wet processing, chemical contamination, and frequent high-heat cleanings are needed. These systems carry an higher price point but can be the most value-driven option due to their long-term durability in facilities that need to stay operational.

- Builds in Moisture Mitigation.

- Can coat new concrete in 7 days.

- 5-Year Warranty – Labor and Material.

- Impact Resistant.

- Thermal Shock Cycling.

- Highest wear resistance.

- Quartz texture for slip-resistance when wet.

- Novolac topcoat option for the best chemical resistance.

Limitations…

- The initial price point can be strong, but when factoring in long-term durability, it takes considerable risk off the table for business managers in food production facilities.

Frequently Asked Questions

Let’s Get Started

Contact your Project Leader or Request a Quote so that you get the BEST WORK for your floors.